The fully automatic sectioning device is capable of cutting up to 96 paraffin blocks as well as delivering 400 sections mounted on slides, registered, dried and ready for further analysis.

All in just 4-6 hours – and without the intervention of a user along the way, which gives a crucial capacity boost to the laboratory.

Fewer hands are involved, and far more samples come through the system in less time for the benefit of both clinicians and patients. But what about the quality?

The goal is improved diagnostics

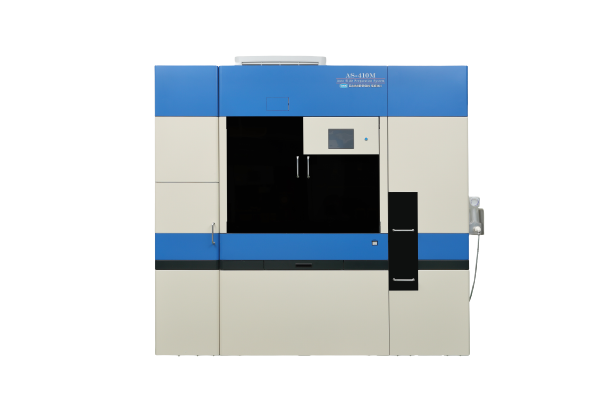

In fact, quality is the core focus of the machine. The AS-410M is equipped with an advanced precision microtome and has automatic blade replacement along the way.

All blocks are measured and adjusted automatically so that they are optimally angled in relation to the microtome knife. The cutting takes place with precise timing at a controlled temperature, which gives cuts with very high uniformity. In addition, the machine can be set to detect the surface photographically, so that the cuts are cut with the largest possible tissue surface in the block.

The result is an extremely high cut quality that creates the perfect starting point for analysis and diagnostics.

Created for digital pathology

Our position at Axlab is that new technology must support digital pathology. Precisely AS-410M is ready to be connected to LIS systems, and with its high quality, the sections are optimal for quality scanning. ID and patient safety are also digitally integrated.

The barcode on the cassette is read automatically and information is printed directly on the slide.

Axlab is the center of fully automated sectioning

Based on our experience and service standard, Dainippon Seiki Co., Ltd. selected Axlab A/S as the exclusive distributor of AS-410M in Europe and the USA.